Skip to content

Projects

Tennessee Wings of Liberty Museum

Clarksville, TN

Fort Campbell Historical Foundation

Learn more

Henry Ford Health Destination: Grand

Detroit, MI

Henry Ford Health

Learn more

Intermountain Health Lutheran Hospital

Wheat Ridge, CO

Intermountain Health

Learn more

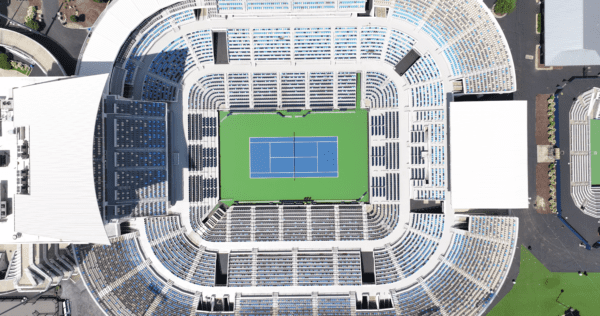

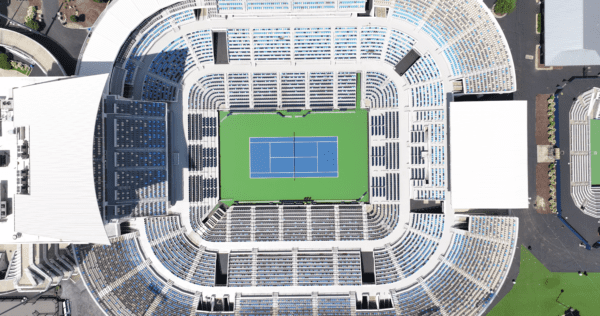

Cincinnati Open Campus Renovation

Mason, Ohio

Cincinnati Open

Learn more

Scotford Solar

Scotford, Alberta, CA

Silicon Ranch Corporation

Learn more

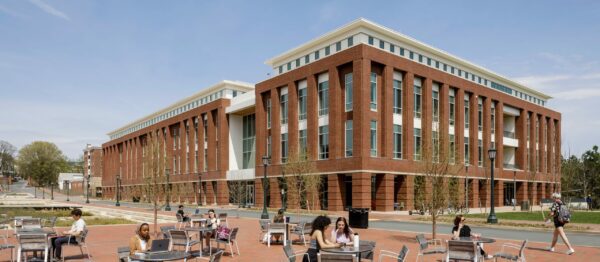

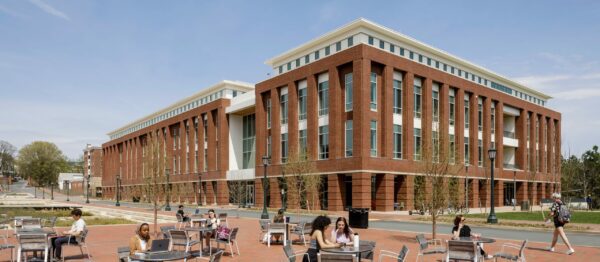

Student Health + Wellness Center

Charlottesville, VA

University of Virginia

Learn more

Wilson Sports + Entertainment Complex

Wilson, NC

The City of Wilson + NSV Wilson, LLC

Learn more

Wallace Battery Cell Innovation Center

Warren, Michigan

General Motors

Learn more

Hudson’s Detroit

Detroit, MI

Bedrock Detroit

Learn more

Skip footer navigation