Barton Malow was chosen as the general contractor for the construction of a Hot Briquetted Iron (HBI) facility on a 130-acre site in Toledo, Ohio that will produce 1.9 million tons of briquettes annually. The facility utilizes the existing port facilities and includes site infrastructure, raw material, and product handling.

Barton Malow’s ironworker, boilermaker, millwright, rigging, civil, and concrete crews were on site throughout the project providing an integrated approach to their scope of work. The project scope included the anchor bolts up scope for the reformer, including grout, 15,100 tons of owner-supplied structural steel, boilermaker scope, and piping scope. The reformer provides heat to the HBI process. The furnace tower work scope included the structural and mechanical installation of the 480-foot furnace tower, including steel, boilermaker, piping, and equipment installation. Work was completed by utilizing conventional erection and modular assemblies. Modular assemblies were placed using Mammoet’s Liebherr LR 13000, the most powerful crawler crane in the world.

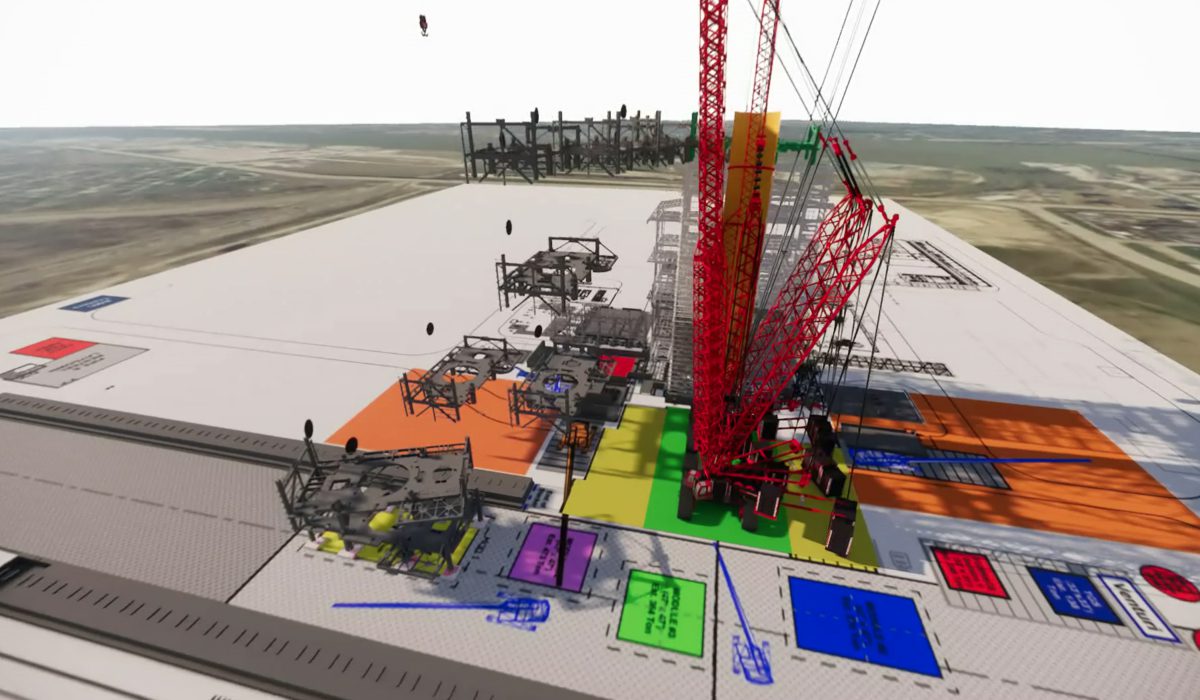

Using Virtual Design and Construction to Maximize Integration

Barton Malow understood the project’s magnitude and need for seamless integration to best execute the work, so our Virtual Design and Construction (VDC) team was engaged early to develop and communicate the build strategy. The VDC team was involved in detailed work planning and installation work packages (IWPs). 4D model presentations with the owner and other contractors were conducted weekly to facilitate site coordination of all work in our areas in real-time.