General Motor’s Brownstown Fuel Cell Lab was the first battery assembly plant in the U.S. operated by a major automaker. It plays a key role in the Chevy Cruise Autonomous Vehicle program with the roof module production for all of Cruise’s self-driving vehicles. The roof modules integrate special equipment for AV operation, such as LIDAR, cameras, sensors, and other hardware, and are assembled on a dedicated line at the facility. Additionally, the Autonomous Driving System Computer and Radar Modules are final assembled and tested at the facility.

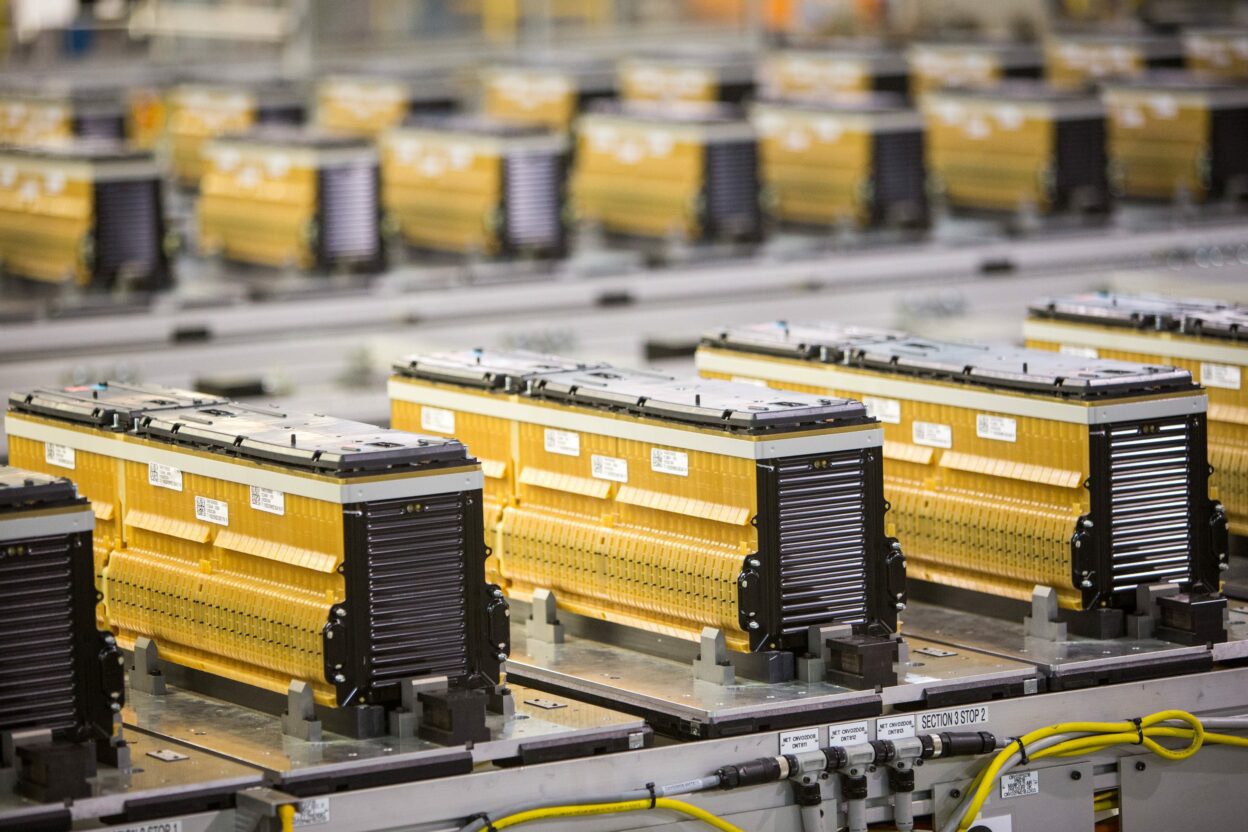

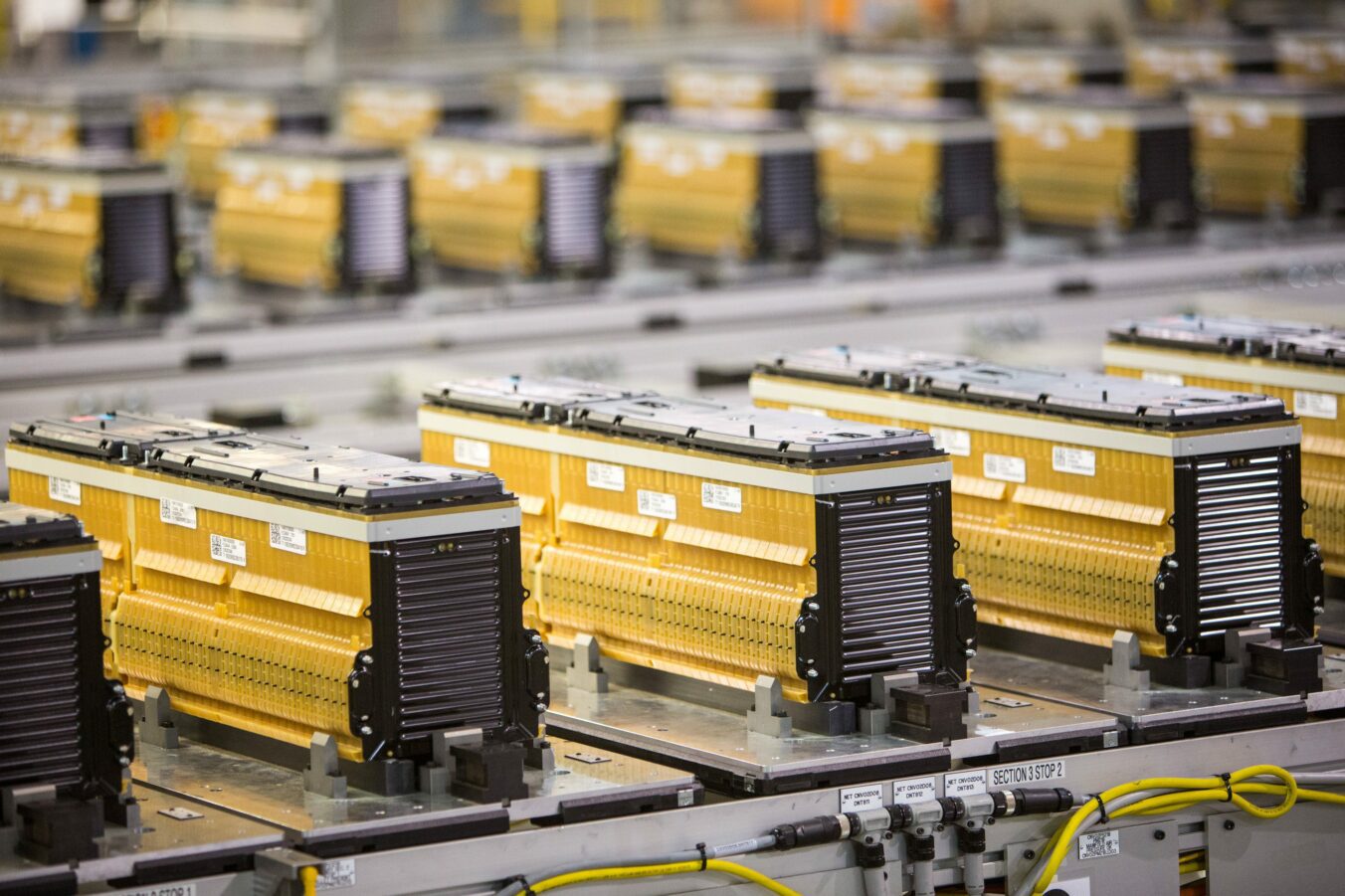

The lab builds plug-and-play fuel cell systems ready for installation. The system includes the stack and all the related cooling, fluid, gas and electrical components, assembled into a module. Fuel cells combine hydrogen and oxygen to generate electricity through a chemical reaction.

The plant was converted from an empty warehouse into a production-ready battery manufacturing site in just five months. Battery assembly lines consist of three primary areas: Section/Module Stacking, Section/Module Final Assembly, Pack Main Line. Autonomous vehicle assembly support consists of a unique production and test area.

The Brownstown Fuel Cell Lab project is another entry in our extensive automotive construction portfolio.