Barton Malow focuses on safety not only before a project breaks ground, but before we even win the project. The benefit of safety planning in the pursuit phase allows our teams to discover all possible jobsite hazards before the project starts, and to ensure that all safety costs are captured and included in the estimate to present to the client.

Barton Malow uses a collection of software platforms to keep workers safe. The hazards identified, along with the corrective measures needed, are highlighted in our Installation Work Plans (IWP) using BIM 360.

A thorough review of design documents helps the Virtual Design and Construction (VDC) team understand project logistics to determine what tools to use to bring the project to life.

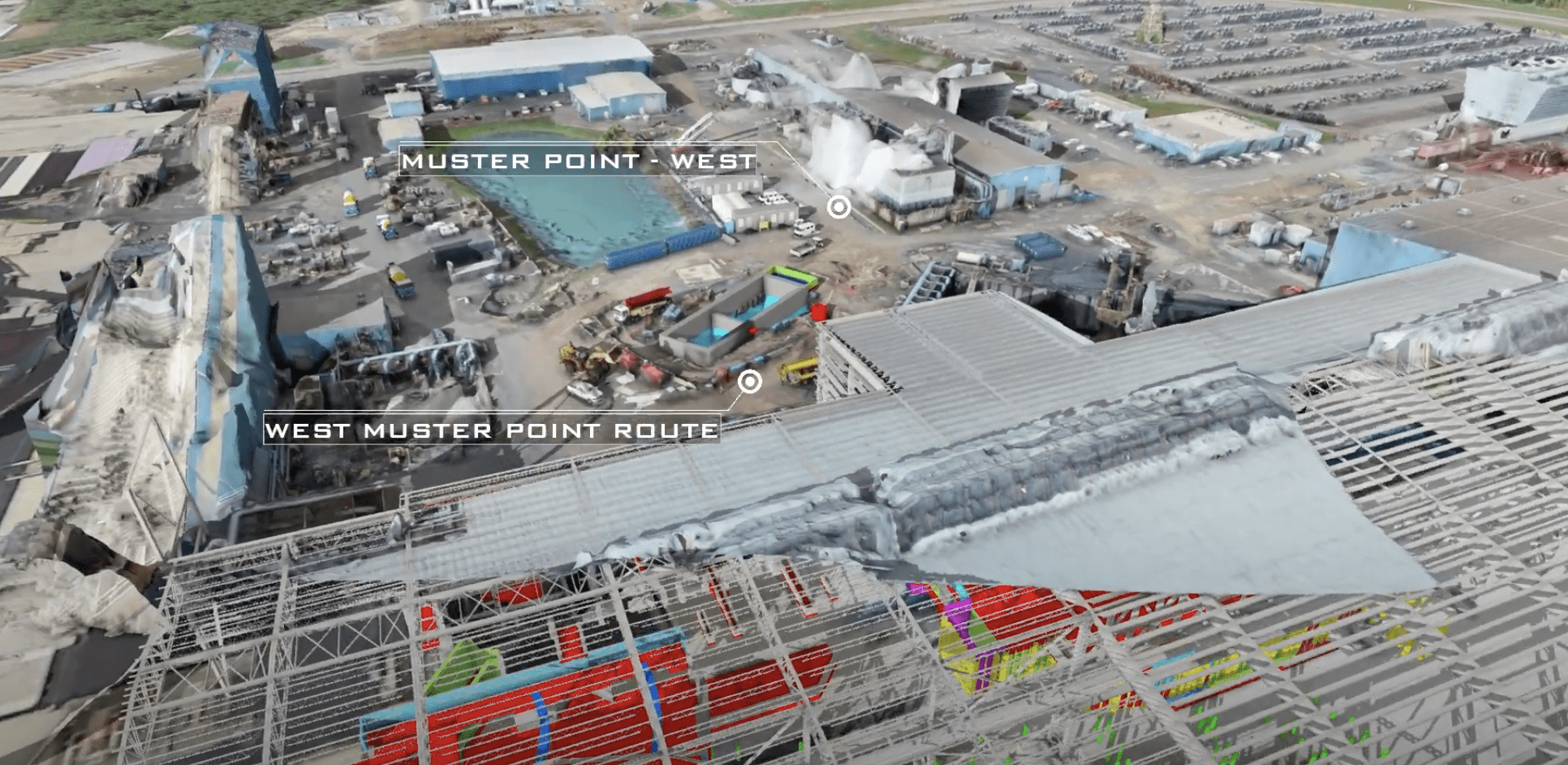

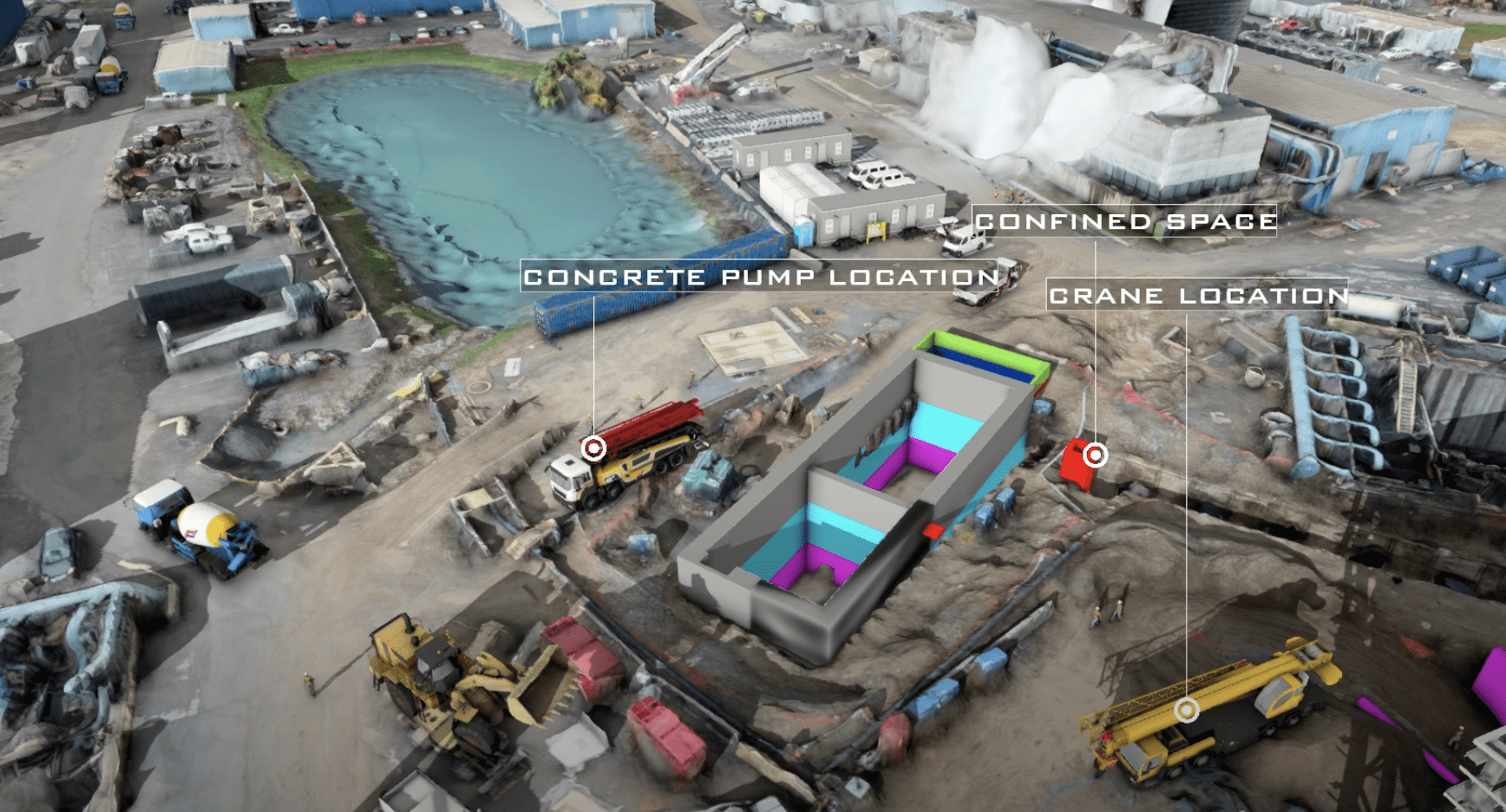

By pairing a drone image with a 3D animated model, our teams can view the construction sequence and project flow, egress constraints, and potential safety hazards. Hazards are highlighted and clearly identified, allowing the team to re-work the plan to eliminate hazards not only before the project breaks ground; this work takes place in the pursuit phase, before we have won the project.

Examples of hazards that can be identified and eliminated before the start of a project:

- Location of all equipment on site

- Where workers will be present

- How different floors will be accessed

- Project sequence

- Multiple sequence scenarios

- Travel paths of both workers and equipment

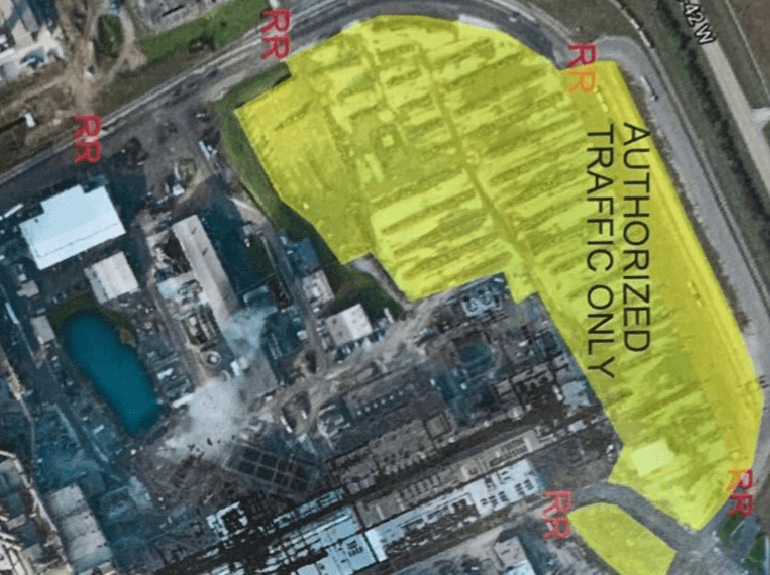

- Emergency vehicle access routes

- Shift length and worker fatigue

- Overlap of equipment

Examples of items we include in our logistics plans:

- Orientation Area

- Local Hospital and Emergency Services

- First Aid Stations

- Emergency Responder Location’s

- Emergency Routes on the Project Site

- Evacuation Routes

- Shelter Areas

- Rescue Plans

- Site Utilities

- Overhead Obstructions

- Swing Radius of Equipment

- Construction Traffic

- Site Activities

- Confined Spaces

- Fuel Storage

- Trailer and Storage Areas

To build it safe, without exception requires prioritizing safety in the pursuit phase.