Barton Malow is constantly working towards finding the most effective and efficient ways to serve our clients’ growing needs through innovation, technology, and continuous improvement. Learn more about where we came from, what we’re doing, and where we’re going next.

Building with the American Spirit People Projects Communities

100 years of operation Explore Our History

3.5K Team Members Across North America Work With Us

111M Hours Worked in 5 years View Our Safety Commitment

Projects

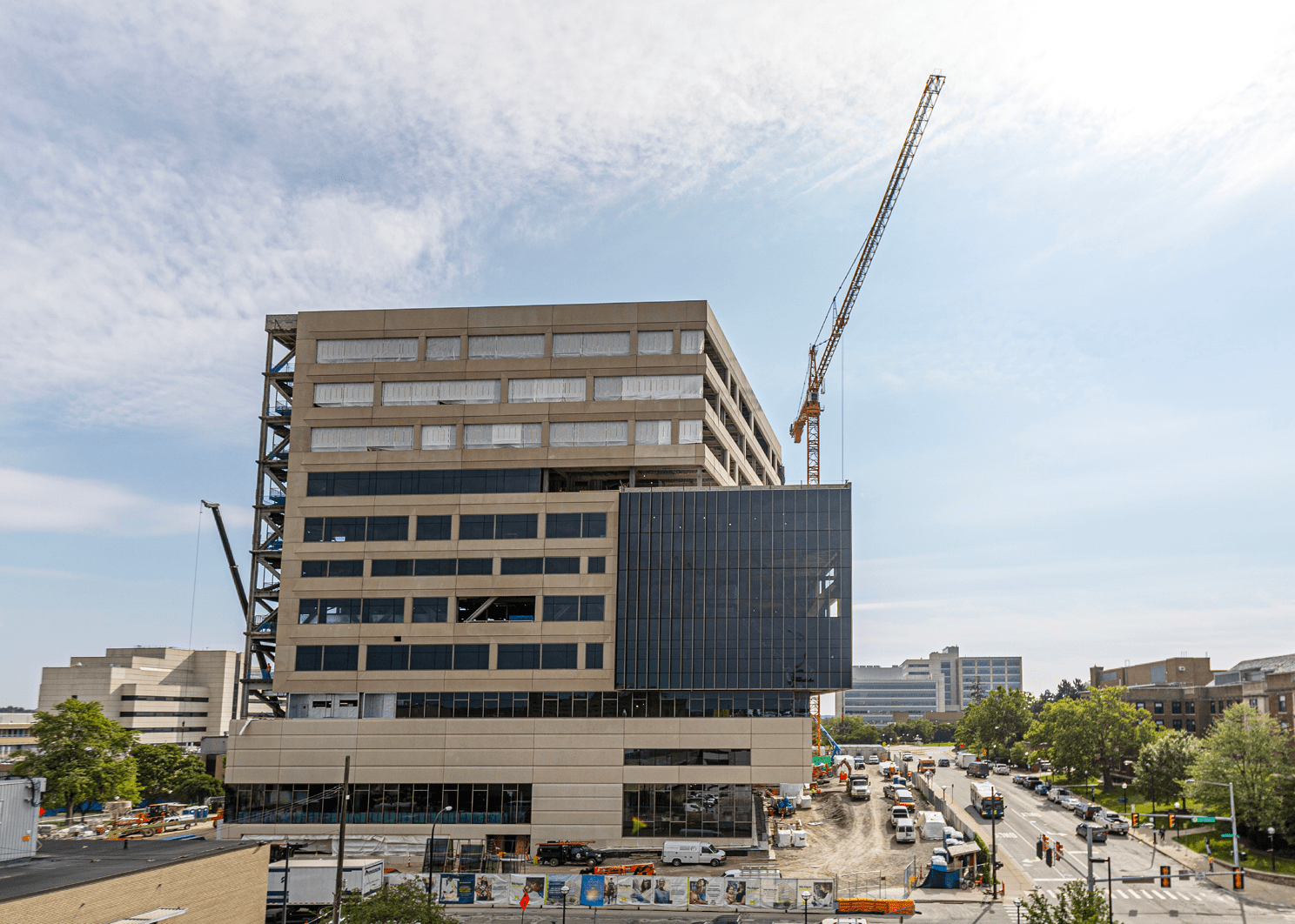

Hudson’s Site Construction Reaches New Heights

April 11, 2024 4 minute read

People

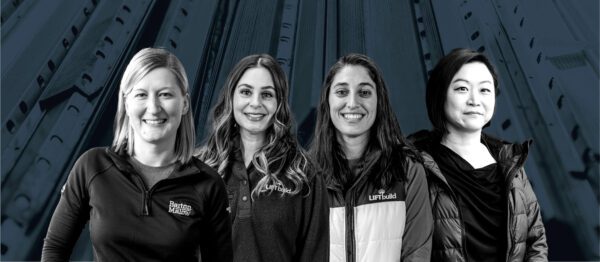

Women in Construction: Transforming the Business

March 13, 2024 1 minute read

Communities

Piedmont Concrete Contractors is Laying Central Virginia’s Foundation

March 7, 2024 5 minute read

People

Listen to ‘Said Differently – Beyond the Build: Kim Hoffman’ Now

March 5, 2024 1 minute read

People

Women in Construction: Hoisting Engineer Harlie Crist

March 4, 2024 2 minute read

People